Page 1 of 2

Lesney car Axels help please......

Posted: Mon Oct 22, 2018 7:29 pm

by wolfie

Hi there.

I was just wondering if anyone could give me any tips on replacing axels on Lesney cars.

I have been using 60g x 40mm panel pins and cut to size then crimp the end you cut but im thinking this could be done better does anyone have any tips.

Thanks Wolfie

Re: Lesney car Axels help please......

Posted: Tue Oct 23, 2018 3:06 pm

by AJR

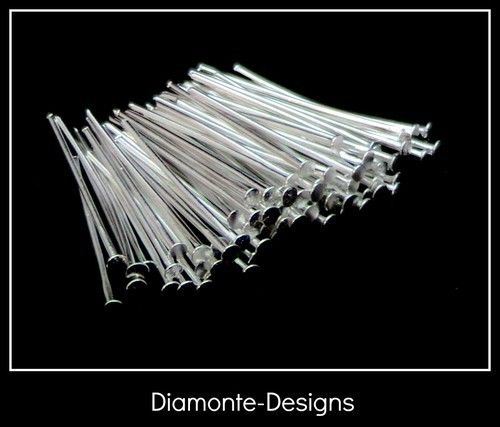

I use hollow tube of the correct diameter (aluminium, brass or copper ... whichever is cheapest on the day) then plug the ends with cut down large head sewing pins.

As large head sewing pins are hard to find (the heads are usually the same diameter as the axle), look around for "jewellery findings". These look like long pins but are of soft metal with larger heads. Just cut to size and push home (either bend for an interference fit or add a dab of glue.

- s-l500 (1).jpg (26.98 KiB) Viewed 8182 times

Re: Lesney car Axels help please......

Posted: Tue Oct 23, 2018 10:17 pm

by wolfie

Hi there thanks for the reply where would i find the hollow tubes? on ebay or someting or a hardwear shop? im in the uk thanks

Re: Lesney car Axels help please......

Posted: Tue Oct 23, 2018 10:22 pm

by johnboy

Re: Lesney car Axels help please......

Posted: Wed Oct 24, 2018 5:24 am

by Tinman

ADMC Code3 is Andy McCoy, a superb craftsman (customs and restorations) and fellow collector. All his products are excellent and he's a great guy to deal with. I highly recommend Andy.

Re: Lesney car Axels help please......

Posted: Wed Oct 24, 2018 2:35 pm

by misterpop

As do I.Great products from Andy ,I use them all the time for my Dinky and Vintage diecast restos.

Re: Lesney car Axels help please......

Posted: Wed Oct 24, 2018 5:39 pm

by AJR

where would i find the hollow tubes

They are available from all good hobby shops. A couple of quid buys about three foot of tube. If no hobby shop near, order online or use eBay but then there is postage.

Most hobby stores stock KS Metals ......

http://www.ksmetals.com/

- _wsb_493x393_Carded+Items.JPG (30.86 KiB) Viewed 8131 times

Re: Lesney car Axels help please......

Posted: Wed Nov 21, 2018 5:08 am

by SupraBob

Unfortunately the MM sizes shown in the previous post will not work for our purposes. The Lesney axels are 1/16 inch, or about 1.6 MM. Here in the U.S. Hobby Lobby carries 1/16 inch tubing. I was also able to find the "jewelry findings" pins, however the heads are too small to simulate the Matchbox hubs. Have to keep looking, or figure a way to modify the pins that I have. I am thinking of putting a glob of soldier on the end of the pin, and then forming it in the shape of a Lesney hub by chucking the pin in a dremel tool and forming it on a file, as Marty does with his nail heads in his Marty's Matchbox Makeovers videos. I see more experimenting in my future this winter......

Bob

Re: Lesney car Axels help please......

Posted: Sun Nov 25, 2018 2:53 am

by SupraBob

I have determined that regular "general purpose" soldier does not work with aluminum. I am going to experiment with solid aluminum rod, and try to form domed ends using Marty's technique. I tried using the nails, either my nails are too hard, or my drill press needs to be set to a higher speed. I am hoping that aluminum will be easier to form. Keep everyone posted.

Bob

Re: Lesney car Axels help please......

Posted: Sun Nov 25, 2018 4:41 pm

by Tinman

SupraBob wrote:I have determined that regular "general purpose" soldier does not work with aluminum. I am going to experiment with solid aluminum rod, and try to form domed ends using Marty's technique. I tried using the nails, either my nails are too hard, or my drill press needs to be set to a higher speed. I am hoping that aluminum will be easier to form. Keep everyone posted.

Bob

Soldier won't stick to aluminium or mazak. It will stick to copper or brass tubing and rod (as well as copper plated mazak).

I noticed that Marty claims to use a "modified nail" as the tool in his drill press. Using a metal for the tool, which is the same hardness as the metal you intend to tool, seems like a fools errand. When I was using the drill press for axle ends, I used a modified hardened (censored) as the tool and another as the cradle. I stopped using the drill press due to concerns that it made the restored model much more difficult to spot in photos and thus could possibly lend itself to fraud in the hands of third party individuals with ill-intent.

I'm a huge supporter of restorations and even recreations of rare models. However, I do not support those who attempt to make these models indistinguishable from the real ones. Modelers (such as Nik the Greek) who go to great lengths to make their models look perfect are indeed fueling fraud. We repeatedly see Nik's models finding their way into the hands of known fraudsters and being resold to the unsuspecting. There have even been some cases where collectors have purchased these kind of models and displayed them here. They display them here in attempts to whitewash the model and give them authenticity. Fortunately, members have rooted out and exposed these individuals and the models in question. I would prefer that people leave the axle ends unmodified or use one of Andy McCoy's handy tube & pin kits to create new axles.

I just ask that people be careful with restorations and recreations. They can look wonderful without having to be so exacting as to fool the unsuspecting.