| Lesney Factories & the production lines |

|

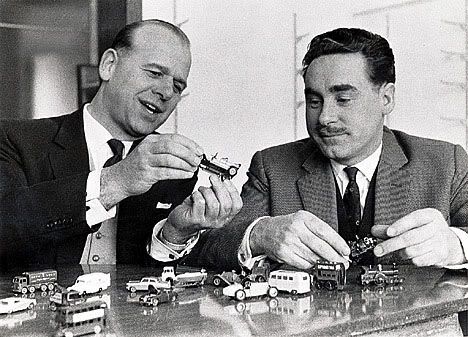

Leslie Smith & Jack Odell

|

The Rifleman public house at Edmonton in north London was where in 1947 Leslie Smith and Rodney Smith who were unrelated School friends decided to put their war gratuity pay into a manufacturing venture using a diecasting machine they had purchased from Rodney's employer DCMT (Die Cast Machine Tools). Rodney had kept his job with DCMT to help with finances, They combined their first names to make "Lesney" and as they were undecided as to what they would be making the company was simply called "Lesney Products".The work began to roll in and soon they decided they would need a toolmaker, At the time Toolmaker Jack Odell who was also a DCMT employee was looking for a place to set up his own manufacturing equipment and Lesney offered him room at the Rifleman. Jack was soon offered a partnership in the budding Lesney company. They found that orders slowed during the Christmas period so began experimenting by making the very first of what went on to become many millions of "Matchbox" toys. |

The backbone of Lesney was the automatic die casting machines shown here in action, These automatic machines were designed by Jack Odell as was most of the equipment used by Lesney. When for the very first time Jack Odell switched on an automatic die casting machine he looked around to find the factory had been completely deserted, The workforce had fled in fear of being sprayed with molten Zinc! |

|

|

As time went on Lesney used more and more plastic parts in their toys, To begin with they had no plastic molding equipment at all so everything had to be made for them, Eventually Lesneys own plastics department rivalled the die casting section as there were just as many plastic components needed as there were for Zinc (Mazac) |

Another example of Jack Odells technical genius, One of these tubs holds the plastic tyres and the other tub holds the wheel hubs, The machine at the front press fits the tyres onto the wheel hubs so they are all ready for fitting onto the axle. |

|

|

This photo was not actually taken in the Lesney factory but it is an interesting piece of History linked with the production of Matchbox toys, It is a photo of the electro-plating equipment which was owned by Spegelstein & Sons an electro plating company based in Wallis rd in Hackney - just down the road from Lesneys factory, Spegelstein's did all of Lesneys metal plating for them in the very early days before Lesney had their own electro-plating equipment, The large tanks must have held many thousands of parts, most of the plated parts were destined to become vehicles in the Models of Yesteryear range. photo courtesy Dave Eason |

|

To begin with all painting was done by outside contractors but eventually Lesney developed their own system of painting and drying the castings. Here moldings of the 23d trailer caravan are being painted The castings would pass through the spray booth on a conveyor belt which took them straight into the oven for drying. The castings would then be turned over and a second coat of paint was applied to give them an even covering. |

Later Lesney changed the painting process. By mounting the casting to the top of a post mounted on the conveyor it could be fed through the spray booth where the post was revolved at high speed when it passed in front of multiple spray guns so the model needed just the one paint process thereby lowering Lesneys manufacturing costs considerably. Here the K-12 Breakdown truck is being painted.

|

|

|

The assembly line workforce was over 60% Female, Nimble hands being good at putting the small parts together. At the 2004 exhibition one ex-Lesney Lady told me of the "hot cigarette break", A run up the stairs and a quick use of the toilet allowed for one minute to smoke half a cigarette, one minute later a workmate would take a toilet break and the half smoked cigarette would be handed over to the workmate to finish!. |

I believe this is a riveting machine which was used to flare the turret type rivets that attached the plastic windows to the castings and also join the body and baseplate together. Note that there is more than one type of model on the production line, Workers could assemble several different models that were all being transported along the one conveyor belt. |

|

|

Applying the "BP" decals to the 25c Bedford tanker, The first model to use decals was the M2a Bedford Walls ice cream truck, These used solvent applied decals which were not suitable. "They made the factory a bloody mess" - Jack Odell. If a decal was misapplied by either tearing or more commonly by having a corner of the decal folded underneath during it's application no time was wasted in removing it, A second decal was simply stuck over the top of the faulty one. Washing a decalled Lesney model in warm soapy water is usually not a problem but be aware that in the case of models with two decals applied one on top of the other the top decal will fall off after just a few seconds in warm water. |

Packing the toys into boxes must have been a mind numbingly boring job, Next the individual boxes would have been packed into a larger box of 72 models and they would be ready for shipment. Note the strategically placed giftset and garage set boxes which most Lesney collectors can only dream of owning. The giftsets are particularly desirable pieces. |

|

|

The packed boxes ready for shipment, Note the conveyor belt, The factory had conveyor belts everywhere, There were overhead conveyor lines where parts were transported around the factory and Lesney used thousands of open topped metal boxes measuring approximately 15 inches square to contain components. |

All of the buildings in the photograph are part of the Lesney complex at Eastway in Hackney. This view is from the north east, Eastway (road) runs along the front edge of the photo, On the extreme right hand side is the entrance to Hackney stadium where you could place a bet on a Greyhound race or watch the "Hackney Hawks" Motorcycle speedway. The site has been flattened to make way for the 2012 Olympic games |

|

|

The roadsign for Lee Conservancy Road which runs alongside the river Lea, The name of the river Lee or Lea goes back thousands of years and both spellings are correct. |

The Lee Conservancy road factory, This photograph of the eastern corner of the factory was taken from across the river lea on Hackney marshes, The large and modern factory was built in the mid 1960's by which time Lesney had a 5500 workforce to house. |

|

|

Another picture of the same view taken in 1991 by Christan Falkensteiner showing the factory in it's derelict state, To ease the removal of the heavy machinery they simply punched a large hole through the roof and through the floors underneath and lifted everything out with a crane. |

The western corner of the Lee Conservancy road factory taken from the north end of Lee Conservancy road. The gates to the factory were littered with die cast toy car parts, Aged 12 I would collect the parts wishfully thinking I was going to build my own Lesney toy from the parts I had found. I collected lots of parts but I dont think I ever found two pieces that were for the same vehicle. |

|

|

I'm not sure on this one but it looks like the center of the Lee Conservancy road factory photographed from Lee Conservancy looking east. |

Part of the Lee Conservany road complex, This building was just across the other side of Homerton road and was still being used by Lesney Industries until recently. Today (2009) it's future is uncertain because Lesney are no longer there and it is standing empty. Updated, the Homerton factory was demolished inn 2012. |

|

|

|

Left: John "Jack" Odell OBE Right: Leslie Smith OBE Let their memory be to the joy they put into the hearts of little boys everywhere. |