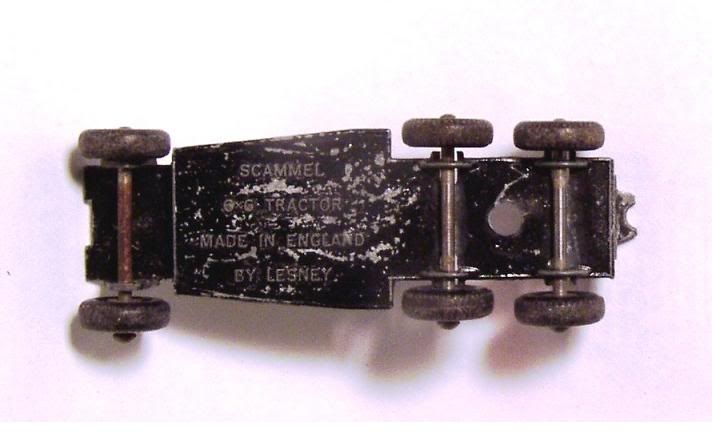

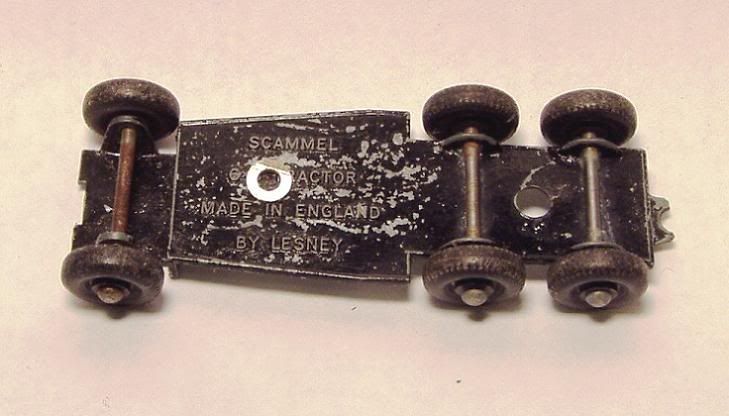

Here is the base from the tractor unit showing the broken hitch loop.

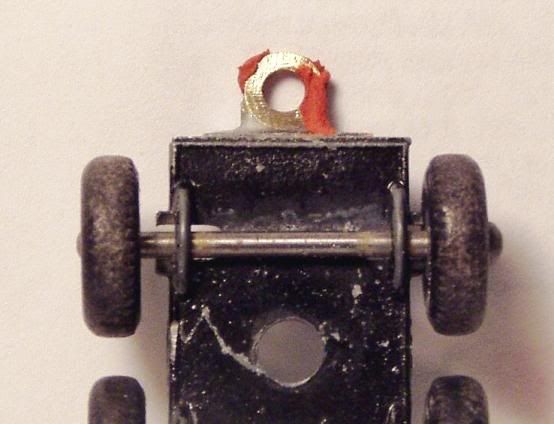

Here is the washer I've selected for the repair. If you look close, you will see I have filed one side of the washer flat (on the radius). That flat spot will face towards the front of the base and allow the hole in the washer to line up with the remains of the hole in the old tow loop.

So that the washer and the remains of the tow loop will mesh together and have the correct profile I have filed the remains of the loop thinner and tapered the thickness. I have filled the washer's thickness too and tapered that thickness in the opposite direction. When the two are glued together with epoxy, they will be flat and have nearly the same thickness as the original loop.

Now that the washer is joined to the base of the tractor, it needs some putty to finish up the cosmetic part of the job. The putty needs to be applied to the top and bottom of the repair.

When the putty is dry, file or sand the tow loop into the final finished shape. Here is the finished tractor. The base and the tractor were primed and painted in their respective colors and new decals applied to the tractor.