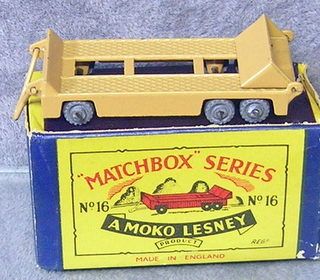

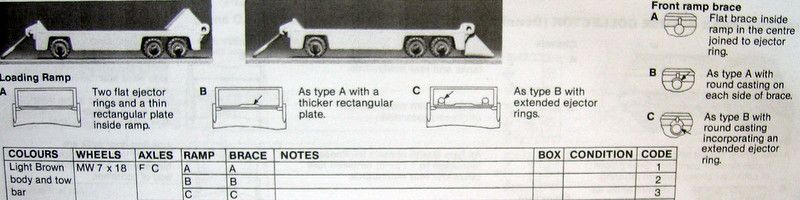

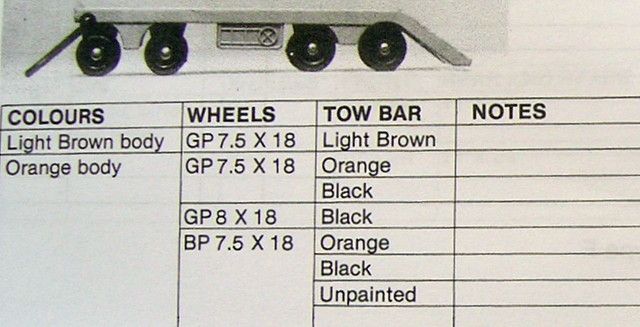

16b Super Atlantic Trailer, issued 1960, length 78mm, box types B-C and D.

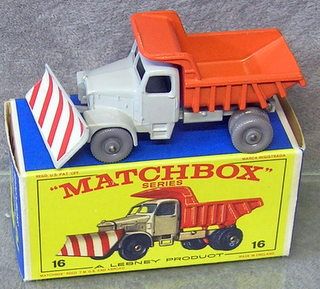

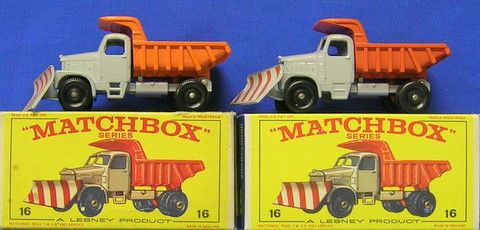

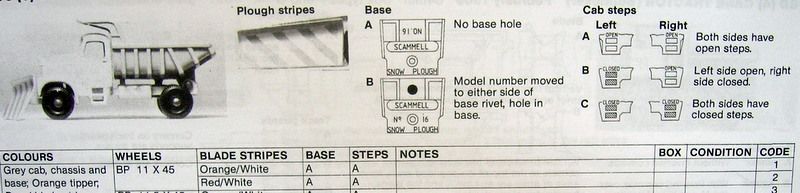

16c Scammell Snow Plough, issued 1963, length 74mm, box types D and E.

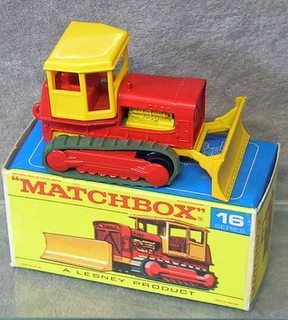

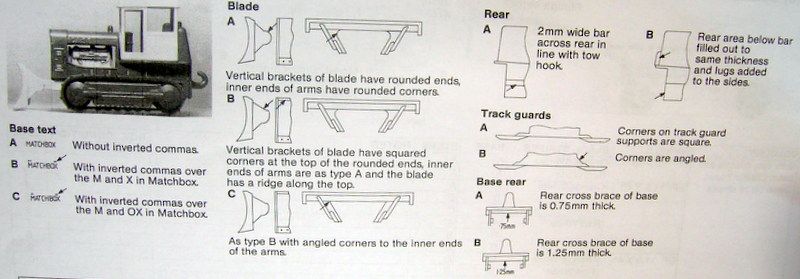

16d Case Tractor (Bulldozer), issued 1969, length 64mm, box type F and G.

The open and closed steps variations.

The two different plastic parts to take the tipper pin in place.

George T.